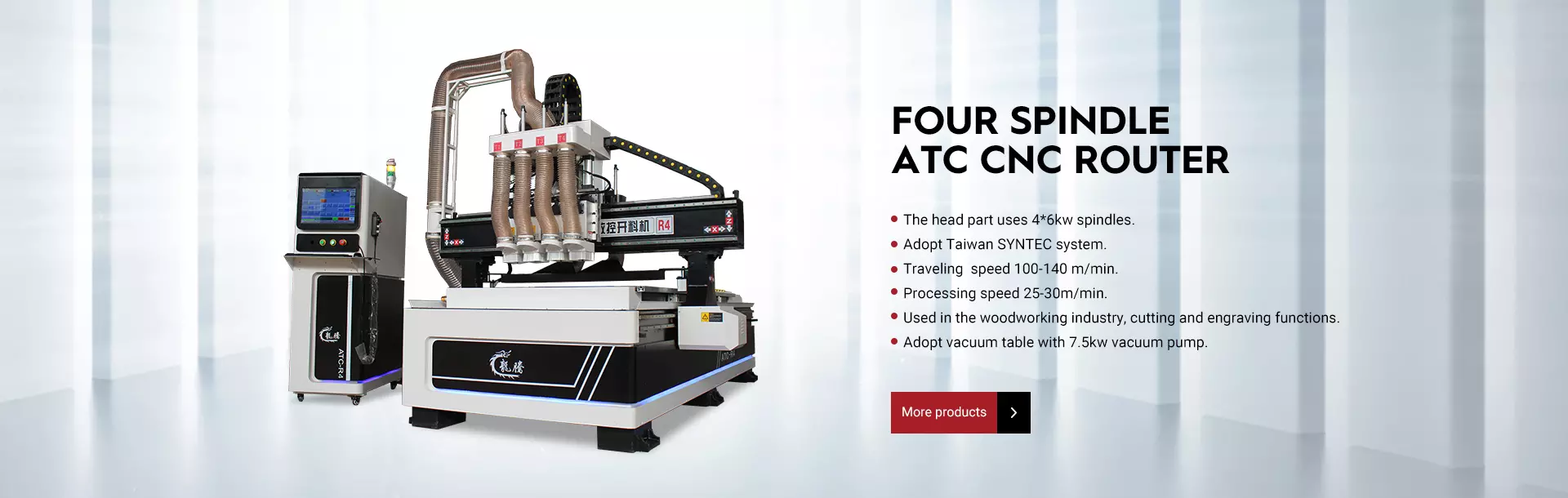

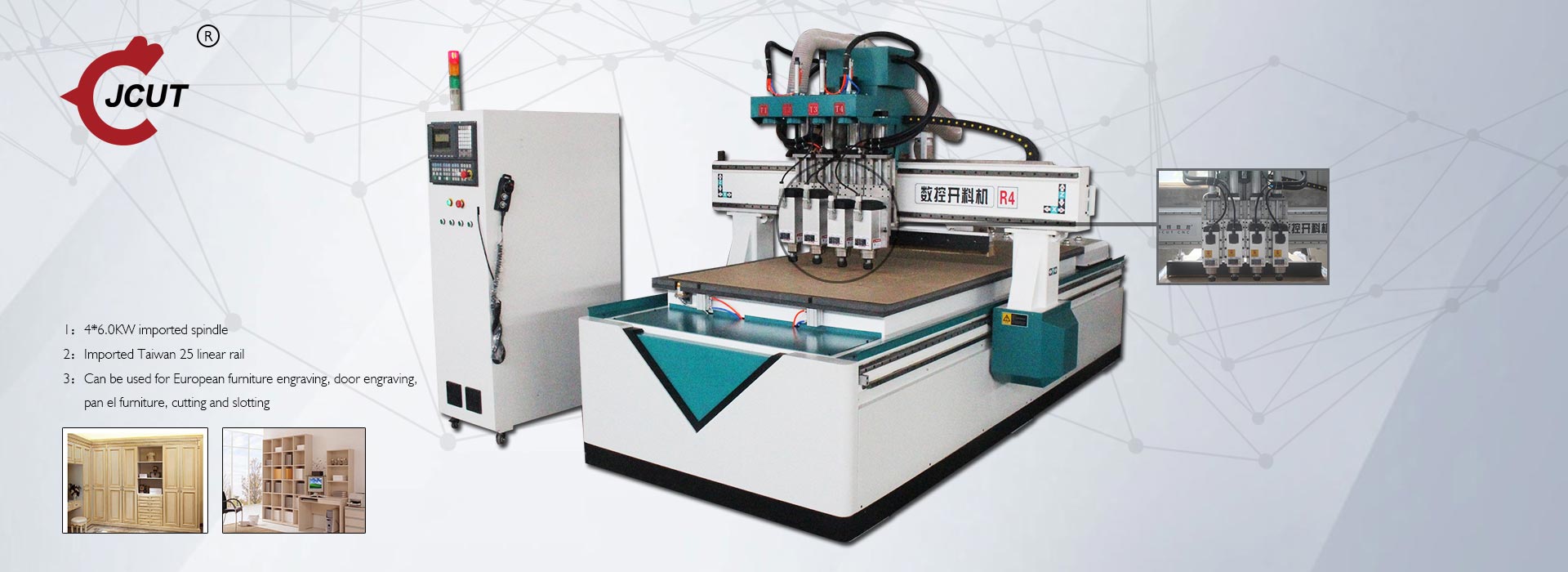

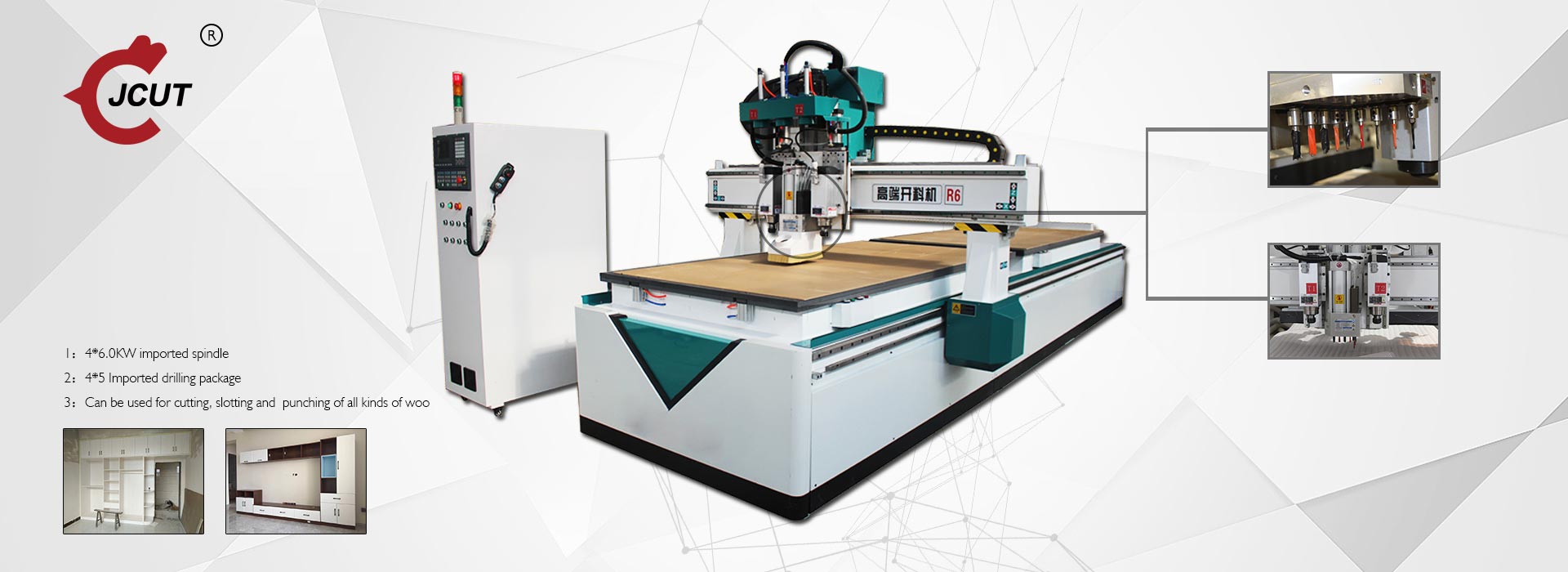

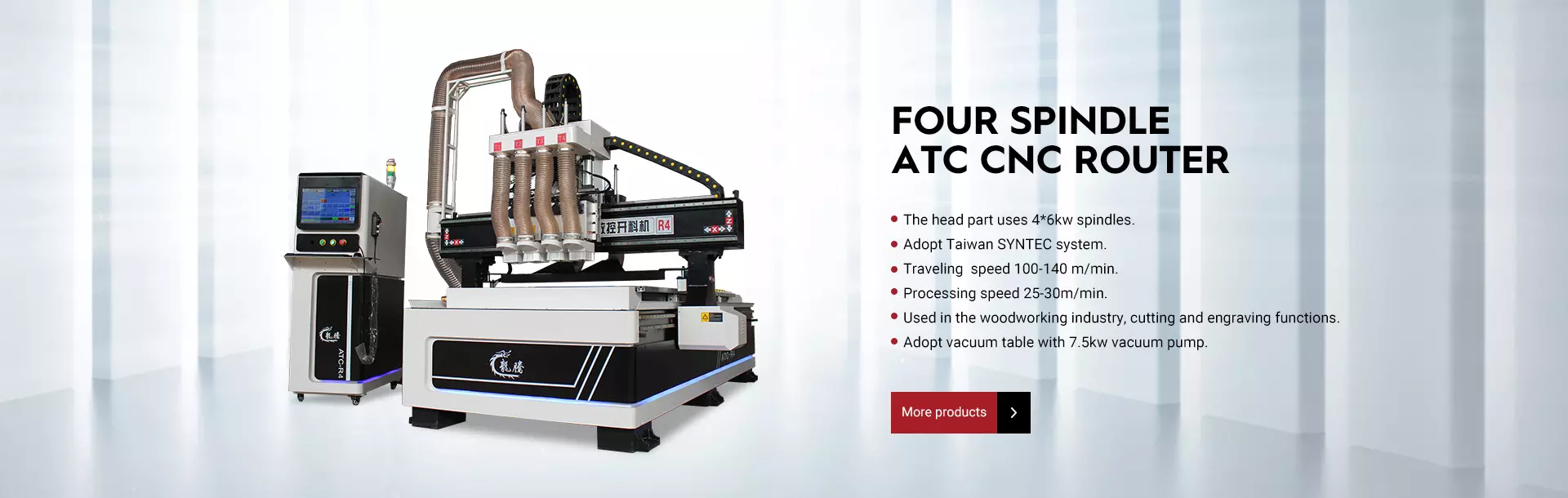

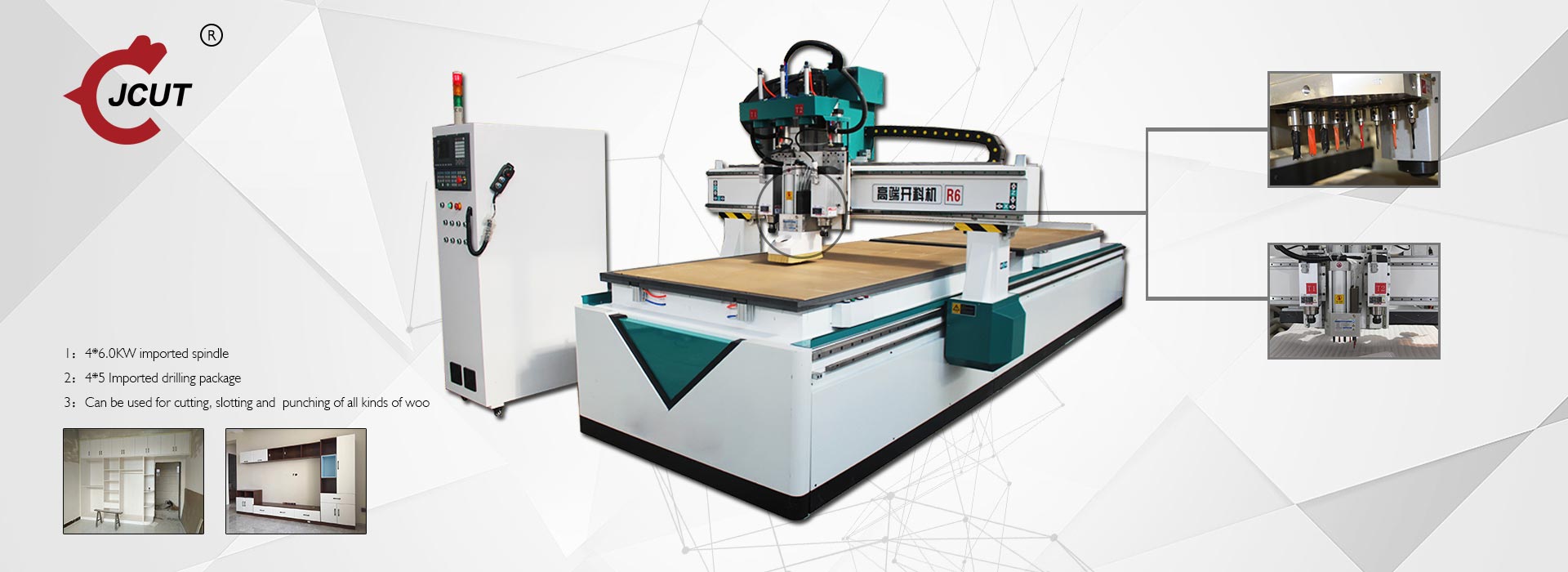

Jinan JCUT CNC Equipment Co., Ltd. is a high-tech numerical control enterprise which specializes in the production of sliding furniture and soft packs of complete sets of panel furniture. The main products are automatic loading and unloading CNC router machine, three-procession cnc router machine, four-procession cnc router machine, multi-procession sliding door engraving machine, sliding door machining center, woodworking engraving machine, stone engraving machine, small engraving machine, metal engraving machine, three-dimensional engraving machine, advertising engraving machine, CNC woodworking machining center. Jcut is an export enterprise of science, industry and trade. The company's business covers all of China and the world. The countries and regions covered by the current business include North America, South America, Australia, Europe, South Asia, West Asia, Russia, and Africa. With the support of friends from all over the world, the company is stricter in the research and development, production and after-sales of products. We adhere to the philosophy of “manufacturing excellent products and serving global friends” and strive to achieve a harmonious and win-win situation between the company and all customers.

Jinan jcut cnc Equipment Co. Ltd.

Jinan jcut cnc Equipment Co. Ltd. Chinese

Chinese English

English