Feature:

Machine Description

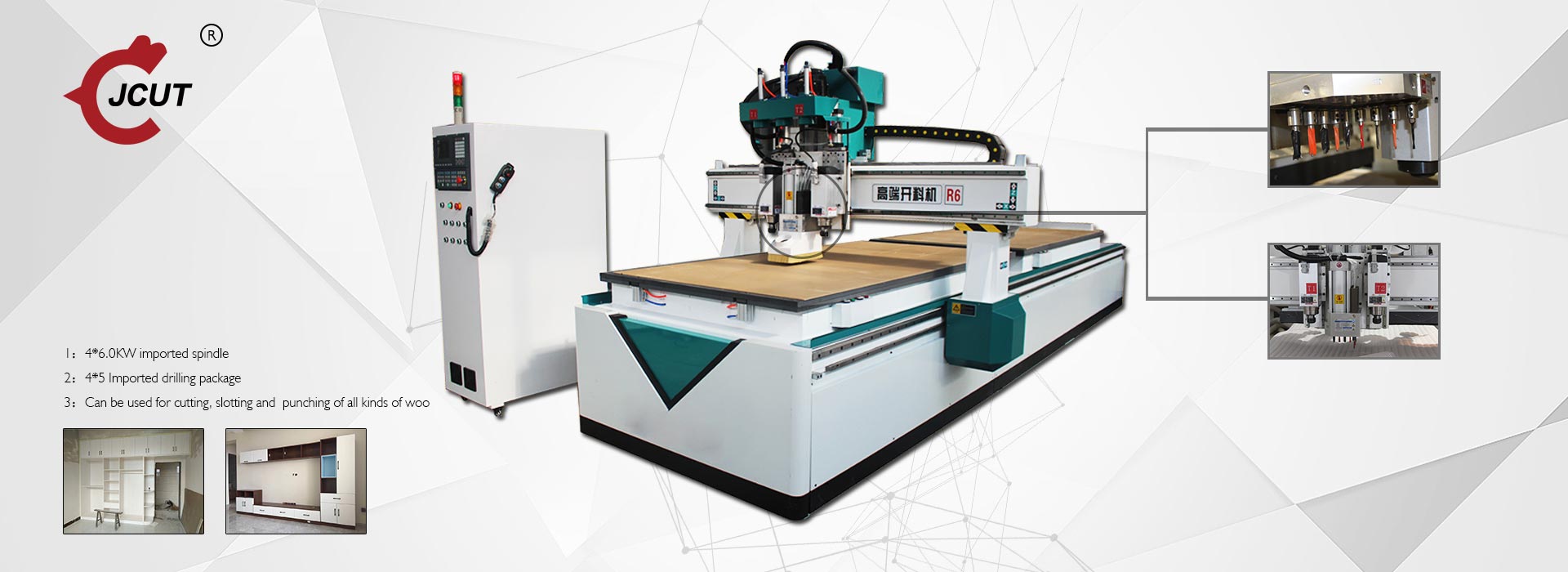

1. Cutting, slotting, punching, carving (simple modeling). The four processes can be used for both cabinet cutting and cabinet door carving. Using advanced automatic tool change program, the program automatically executes processing requirements without manual intervention. Multiple spindles work simultaneously, effectively improving processing efficiency.

2. Equipped with a vacuum adsorption table, the vacuum pump can perfectly adsorb materials of various sizes, and the adsorption effect is good. There is no need to manually fix the plate, which greatly improves the work efficiency.

3. Equipped with servo motor, high-precision gear and imported rack drive, which makes the machine run stably, with low noise, fast speed and high positioning accuracy. And The automatic lubrication system can automatically lubricate and lubricate according to time to ensure the lubrication of the slide screw guide rail and extend the service life of the machine.

4. The machine tool adopts giant gantry frame for high temperature tempering treatment to ensure small deformation, good rigidity, high strength, high durability, and long-term use without deformation, .Gantry movement, gantry integral casting, sturdy and durable, long-term use without deformation.

5. Using advanced automatic tool change program, the program automatically executes processing requirements without manual intervention. Multiple spindles work simultaneously, effectively improving processing efficiency.

6. Using power-off memory to ensure that processing can continue in the event of an accident (broken knife) or the next day.

Machine Application

The inline tool change machining center is suitable for woodworking industries such as panel furniture, cabinet doors, office furniture, custom furniture, and door industry. Processable plates: multi-layer plates, particle board, ecological boards, density boards, wave boards and other various boards. The machine can be used in a variety of industries, such as panel furniture, cabinet wardrobes, office furniture, custom furniture, computer desks, wooden speakers, wooden kitchen utensils, etc.

Parameters:

Configuration

|

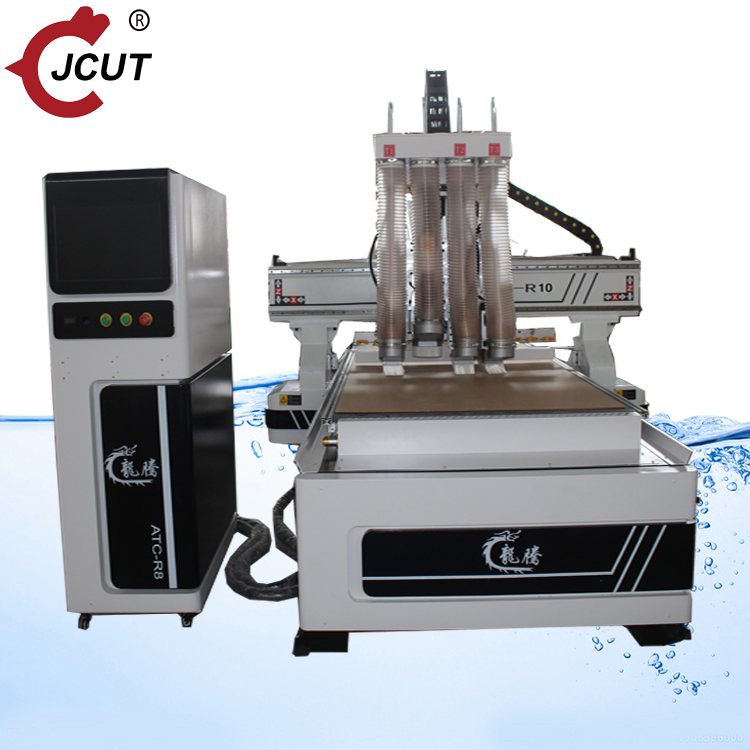

Longteng third generation R10 linear ATC + Four Heads cnc router |

|||

|

Working area(S*Y*Z) |

1220*2440*200mm(support length 2800 customization) |

Speed of spindle |

0-18000/MIN |

|

spindle |

GDZ 9KW*1+3.5kw*3 |

Tool magazine |

12 tools(support 16 tools customization) |

|

Serve motor |

Leadshine 1500W serve motor |

Serve driver |

Supporting serve motor driver |

|

inverter |

11kw inverter |

Tool change speed |

Top speed |

|

system |

Taiwan LNC system |

Transmission track |

TBI Original 25 square rail |

|

Slide |

TBI Original 25slider |

Ball screw |

TBI 2510 Ball screw |

|

Cable |

High flexible shielded towing chain cable |

Limit |

Special for cutting machine |

|

rack |

HICK |

Electric element |

Zhengtai |

|

Reducer |

Motovario |

cylinder |

Huadeli |

|

Traverse speed |

100000MM/MIN |

Working speed |

35000MM/MIN |

|

Vacuum pump |

Water cycle 7.5KW |

Dust collector |

Double bag 5.5KW |

|

Voltage |

AC380 |

weight |

2600KG |

|

Machine appearance |

Third generation longteng patent structure(independent control cabinet) |

||

|

Bed strcture |

Heavy aging treatment welding bed(five face milling and drilling precision 0.02mm) |

||

|

Gantry |

Crossbeam thick wall square pipe and steel strip welding synchronous bed machining technology the whole cast structure of the column |

||

|

Computer operation cabinet |

Longteng patent cabinet series, fully sealed large screen intelligent operation cabinet |

||

|

z axis components

|

Z axis motor lock function, Z axis motor screw support seat |

||

|

Vacuum adsorb table |

Patent design 50MM adsorption caliber, PVC pipe connection sealing good, do not run plate |

||

|

Tool sensor way |

Auto tool sensor |

||

|

Feed positioning |

Double-sided all-package positioning cylinder with aluminum strip |

||

|

Auto unloading |

Fully automatic tiled horizontal push blanking belt auxiliary aluminum bar stop function |

||

|

Dusting method |

Automatic spindle partitioning integrated dust removal and secondary dust removal. |

||

Jinan jcut cnc Equipment Co. Ltd.

Jinan jcut cnc Equipment Co. Ltd. Chinese

Chinese English

English